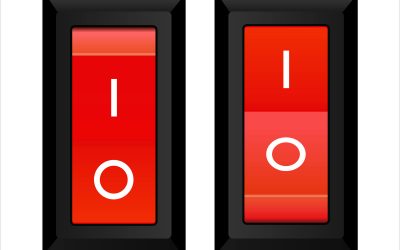

Inclination switch

Table of Contents

Inclination Switches in Action

The inclination switch, also known as a tilt switch, tilt sensor, or inclinometer, is a type of electrical device that detects changes in an object’s orientation or inclination with regard to gravity. It works on the premise that gravity’s pull is constant, and therefore any change in an object’s angle or orientation relative to the earth’s gravitational field may be observed. A conductive element, such as a ball or mercury bead, may shift within a tube within the switch to make or break an electrical circuit. For more accurate readings, more complex models may employ accelerometers or gyroscopes.

Applications of Inclination Switches

These switches serve a purpose in an extensive variety of applications. Alarm systems can detect illicit movement and provide an alert. They assist in maintaining balance and managing on difficult surfaces in robotics. These switches are used in automotive systems to adjust lighting orientation, check stability, and activate safety features like as rollover protection. They are found in consumer devices such as mobile phones and game controllers, allowing for interactive user experiences. Various varieties of switches are intended to accommodate varying sensitivity levels, angles, and environmental conditions, necessitating careful calibration. The invention of inclination switches has substantially increased the versatility and efficiency of modern technology in a variety of industries.

There are different types of inclination switches, including:

- Mercury tilt switch: This type of switch uses a small amount of liquid mercury inside a sealed glass tube. When the switch is tilted, the mercury flows to one end of the tube and completes an electrical circuit, triggering an action. While mercury tilt switches are simple and reliable, they are being phased out due to environmental and health concerns related to the use of mercury.

- Ball-based tilt switch: These switches use a metal or conductive ball inside a small housing. When the switch is tilted, the ball rolls and makes contact with a pair of electrodes, completing the circuit and triggering an action. Ball-based tilt switches are more environmentally friendly than mercury switches but can be less sensitive and prone to mechanical wear.

- Solid-state tilt switch: These switches use microelectromechanical systems (MEMS) technology or other solid-state sensors (e.g., accelerometers or gyroscopes) to detect inclination changes. They are more accurate and reliable than mechanical switches and can provide digital or analog output. Solid-state tilt switches are widely used in modern electronics due to their small size, low power consumption, and high sensitivity.

Inclination switches can be designed to trigger at specific angles or provide continuous measurement of the tilt angle, depending on the application requirements. They are commonly used in devices like smartphones and tablets for screen orientation, vehicle stability control systems, and tilt-based alarm systems.

You may also be interested in:

people also ask

Inclination switches are used in a wide variety of applications including smartphone screen orientation, vehicle tilt sensors, construction equipment stability controls, alarm systems, and conveyor tilt monitoring.

A simple mechanical tilt switch contains a movable conductive element like a mercury blob or metal ball that makes or breaks contact with electrical terminals when tilted. This opens or closes a circuit to activate a response.

Solid-state inclination switches using MEMS sensors offer better accuracy, reliability, and sensitivity compared to mechanical switches. They have a longer lifetime with no moving parts and can provide analog or digital outputs.

Detection angles depend on the switch design but ranges from a few degrees for highly sensitive types to 360° for some omnidirectional models. Customizable trigger angles are possible.

Calibration and testing ensures the switch is properly aligned and triggers at the correct angles. Methods involve precision fixtures, gimbal tables, and rotation equipment to validate performance.

Mercury is toxic and hazardous if the glass tube breaks. This makes disposal and handling difficult. Safer non-mercury alternatives are now predominant.

MEMS and nanoelectromechanical (NEMS) fabrication allow smaller, lower power, and more sensitive solid-state inclination sensing. Wireless and digital interfaces add connectivity and intelligence.